|

Winterschool: Nanotechnology for the design of functional materials:

|

|

| TU Dresden » ... » Chemie und Lebensmittelchemie » Physikalische Chemie und Elektrochemie » Arbeitsgruppe für Theoretische Chemie » NDFM 2012 |

NAVIGATION

---------------

General Information

General Information

Latest News

Latest News

Location

Location

Topics

Topics

Program

Program

Application

Application

Organization & Funding

Organization & Funding

Poster

Poster

Contact

Contact

Development of dry self lubricating sintered steels for solid lubrication in mechanical engineering

Aloísio Nelmo Klein - UFSC

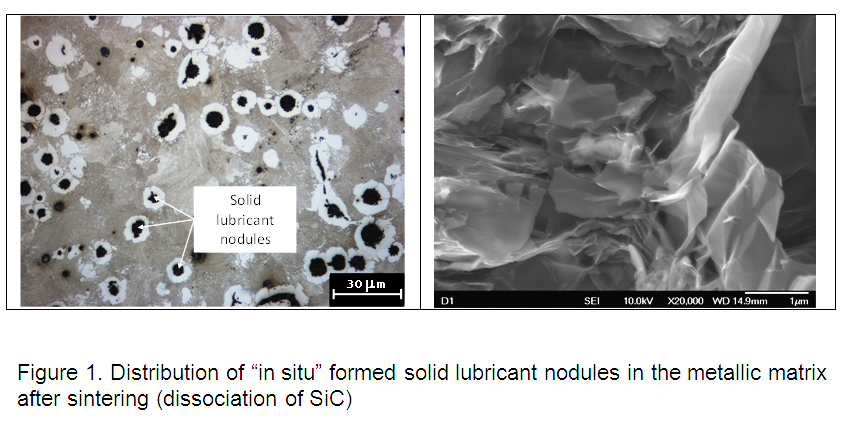

In the current advanced stage of the technological development, functional materials with high performance are required, designed specifically for each particular application. In many mechanical engineering applications, materials that have high strength and high wear resistance combined with a low friction coefficient are needed. It is estimated that about 34% of all mechanical energy produced worldwide is wasted by deficiency in lubrication, being converted into heat by friction. In addition to energy loss, the heat generated affects negatively the performance of the mechanical system. Thus, it is of fundamental importance to maintain the friction coefficient low in mechanical parts where friction occurs, enabling to save energy and increase the durability of the parts and the mechanical systems. In addition, it contributes to environment preservation by reducing the material disposal. One way of reducing wear and friction between contacting surfaces in relative movement is to keep a layer of lubricant separating them. Among the possible forms of lubrication, the hydrodynamic, with the use of a lubricating fluid, is the most used. In hydrodynamic lubrication a film of oil is forced between the surfaces of the moving mechanical parts, maintaining them completely separated while in relative motion. However, the use of fluids as lubricants is often problematic. Examples are applications in high temperature when the lubricating fluid can be chemically degraded and applications in which the fluid may act as a contaminant. Moreover, in situations of limit lubrication, i.e., at the start and stop of each cycle, as well in cases where there are difficulties to form a continuous and stable oil film, contact will occur between the metal surfaces and, consequently, wear will occur. In these cases, the use of dry lubrication, i.e., the use of solid lubricants, may provide the best tradeoff. The presence of a layer of solid lubricant, more stable than liquid films, prevents contact between the surfaces of the components. Solid lubricants can be used in extreme temperatures, under high loads and in chemically reactive environments, i.e., situations where conventional lubricants cannot be used. Furthermore, the dry lubrication is an environmentally cleaner alternative. The solid lubricant can be applied to the surface of the components in the form of films (or layers) or incorporated into the volume of the material in the form of second phase particles. In the case of the application of films or layers, after damage has occurred by wear, the metal-metal contact of the components will be unavoidable and rapid erosion of the unprotected surfaces in contact will occur. Furthermore, besides oxidation, it is usually difficult to restore the lubricant film once it has degraded. As a result, the formation of a dry self lubricating composite in the form of second phase particles embedded in a continuous matrix is often a better solution. Dry self lubricating bulk sintered materials can be produced by powder metallurgy techniques. This Lecture shows and discusses some results of a study intending to develop special new dry self lubricating materials having low friction coefficient combined with high mechanical and wear resistance. The concomitant high mechanical and tribological performance results from the simultaneous implementation of specific requirements related to the mechanical properties of the metallic matrix and the microstructural parameters designed for the composite material, such as hardness of the matrix, degree of continuity of the matrix, sort and amount of solid lubricant added to the material, particle size of the dispersed solid lubricant particles and the mean free path resulting between them. Nano structured solid lubricant nodules can be obtained during sintering via “in situ” reactions between the distinct powder components added to the matrix powders (see figure 1). Parts are produced via powder injection molding and sintered via Plasma Assisted Sintering.